From Frankenstein’s monster to Roy Batty and beyond, humanoid creations have always piqued our fascination.

But the closest we’ve come to bringing the fantasy to life — in real life — is by building robots. Until recently, this strategy hasn’t produced strongly convincing results. Even though a viral tidbit attributed to Stephen Hawking proposed a world where humans would play a role for robots similar to “what dogs are to humans,” it was tough to see us becoming their best friends. Back in 2016, Boston Dynamics’ Atlas robot wasn’t very endearing until a YouTuber brilliantly added a human touch in post-production.

Robot capabilities have come much further eight years later, but what’s the next step? How about realistic, human-like skin, like the Terminator?

One lab announced new developments in robot skin systems that could significantly blur the line between man and machine.

Healthy ‘skin,’ wide ‘grin’

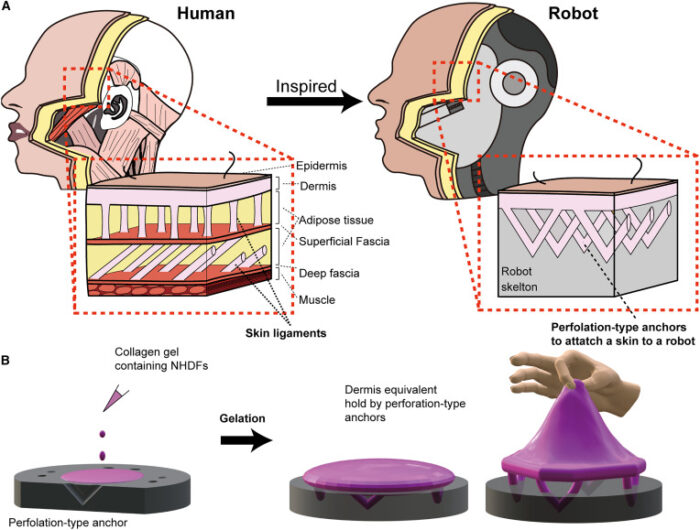

Cultured from human skin cells and secured with attachment systems based on human ligaments, the new material self-heals and adheres to its frame with a stretchy, rebounding quality. Thanks to a “perforation-type” anchor system, it resists loosening and tearing — which have been disturbing giveaways of robot skin up to now.

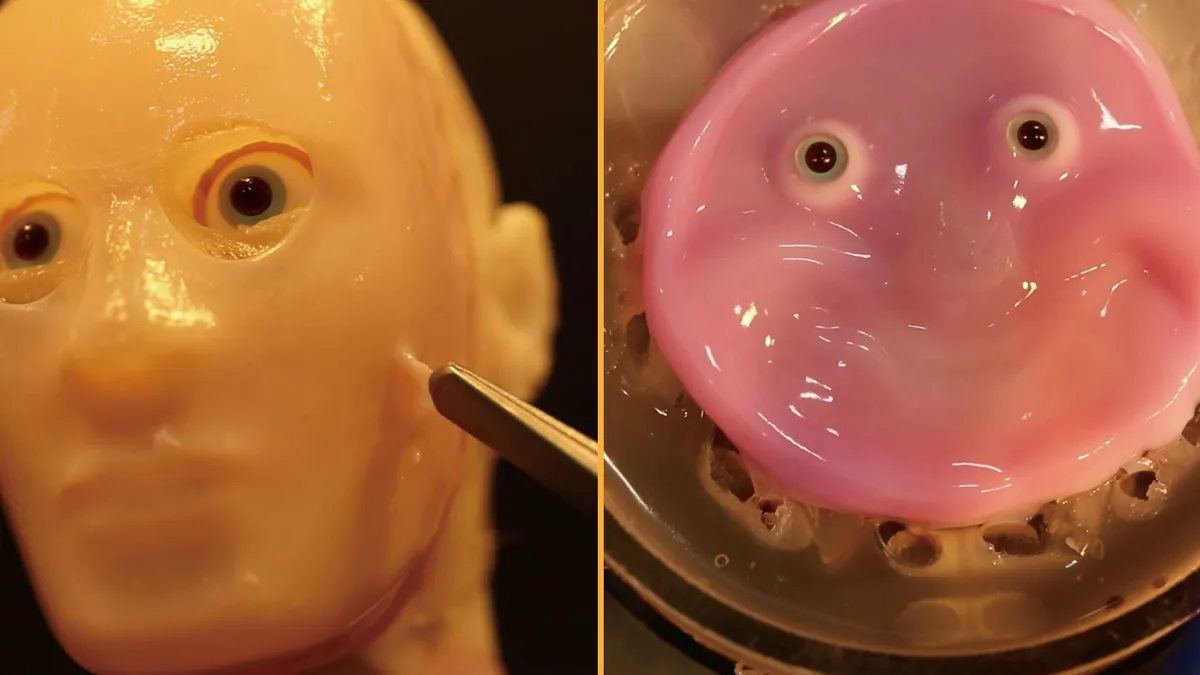

The University of Tokyo lab team announced its findings with a June 25 paper in the journal Cell Reports Physical Science. Uncanny photos and video shows the new cultured skin undergoing “smile” tests — a flat “face” stretched onto a metallic chassis contorts back and forth into a mouthless grin.

Material durability and lasting tension are inherent challenges robotics researchers face while engineering skin. The new, cultured product reverses previous anchoring structures that protruded upward from below, attaching to the skin via hooks. Over time, the skin stretched and loosened around the anchoring points.

The Tokyo team’s artificially grown skin, instead, uses V-shaped hooks that insert into tiny perforations in the robot’s skeleton.

To do it, technicians must essentially paint on the robot’s skin. First, they coat the robot with a water-vapor plasma to make it attract water instead of repel it. Lab techs then smear a skin-forming, “cell-laden gel both onto and into” the V-shaped holes in the robot’s structure. The hydrophilic, or water-attractive, skeleton then pulls the skin hooks into the perforations over time.

Human skin ligaments (left) and the hook system developed by the Tokyo team (right).

Testing will continue as the team seeks better durability. They mentioned the skin can self-heal under minor wear and tear, but did not measure the recovery rate. Human skin maintains the distinct edge in self-repairability for now. The robot skin’s developers are looking to mimic ours as closely as possible.

Study co-author Shoji Takeuchi told LiveScience the team is trying to increase the skin’s nutrient and moisture supply, which “could involve developing integrated blood vessels or other perfusion systems within the skin.”

Another objective is to increase shear strength. Don’t look for ripstop stitching, though. “Optimizing the collagen structure and concentration within the cultured skin” is the target, Takeuchi said.

You can’t stand in the way of progress. So you’d might as well smile about it — whether you’ve got a face made of bone or titanium.